MICRO-VU – 3D OPTICAL MEASUREMENT MACHINES

The main sensor of optical measuring machines is a camera that works on the principle of image analysis. Micro-Vu machines are able to maesure with accuracy in µm not only in XY axis, but in Z axis too. Compared to the more familiar 3D CMM (touch) machines optical measurement is very fast and safe. (Optical measurement is non contact. There is no risk of collision of the machine with the measured part).

Big advantage of Micro-Vu multisensor machines is their versatility, easy to use, wide range of sizes and long service life. The devices do not have special operating requirements, they do not require compressed air and can be controlled from any PC.

We are only one official dealer for CZ, SK and PL.

Micro-Vu machine advantages

- 3D measurement for all types of production

- Possible to add other accessories (touch probe, laser probe, rotary axis)

- For all type of materials (black and white plastics, shiny machined parts)

- Can be operate in the laboratory or in the production hall

- Easy to use software (in many languages)

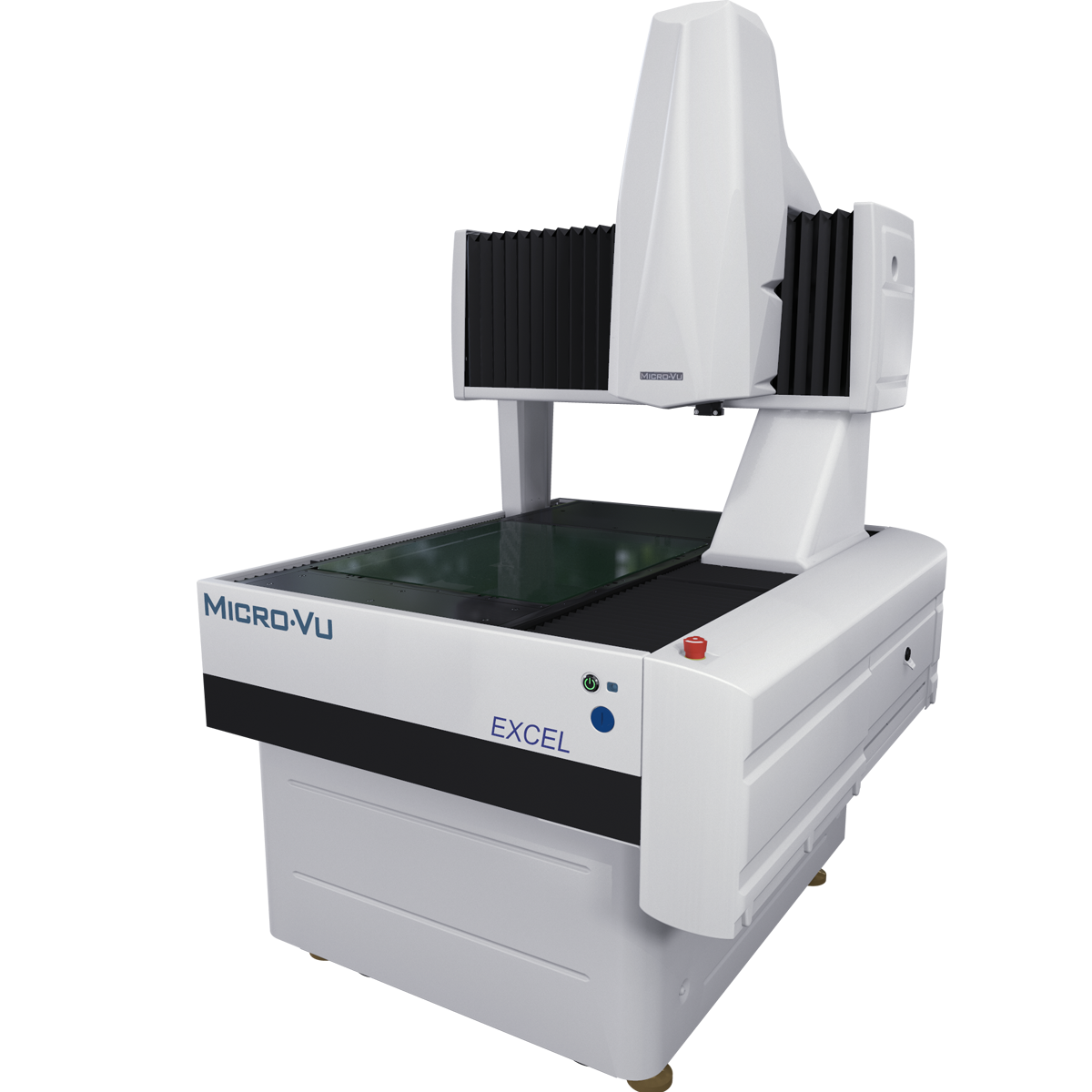

EXCEL

| Construction | bridge |

| Drive | automatic |

| Measuring range XY | 500 – 2000 mm |

| Measuring range Z | 160 – 400 mm |

| Accuracy XYZ | 2,5 + L/200 μm |

| Load capacity | 100 kg |

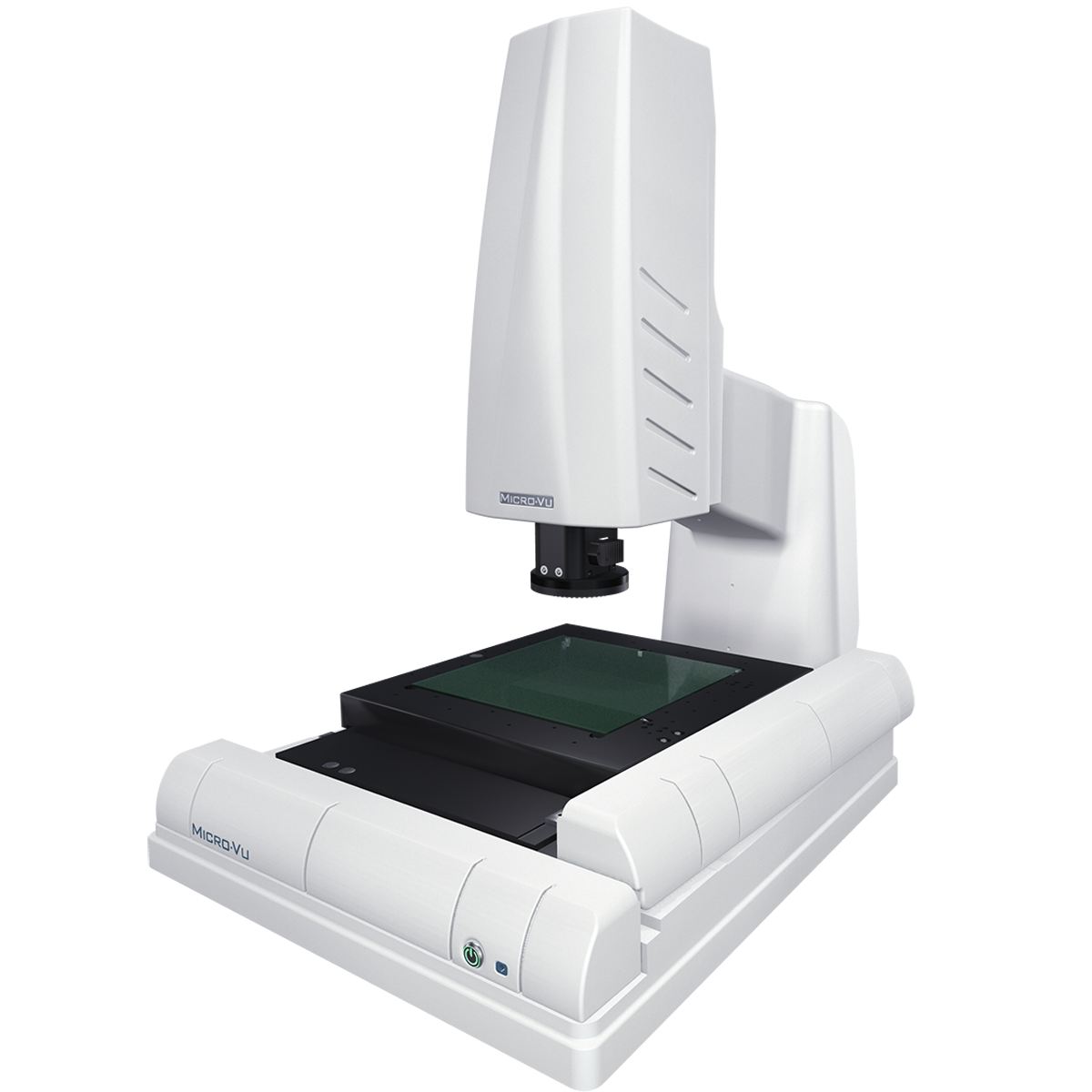

VERTEX

| Construction | table |

| Drive | automatic |

| Measuring range XY | 250 – 315 mm |

| Measuring range Z | 160 – 250 mm |

| Accuracy XYZ | 2,8 + L/150 μm |

| Load capacity | 10 kg |

SOL

| Construction | table |

| Drive | manual |

| Measuring range XY | 160 – 315 mm |

| Measuring range Z | 160 – 250 mm |

| Accuracy XYZ | 3 μm |

| Load capacity | 3 kg |

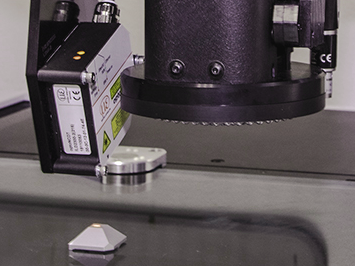

SENSORS

Optical measuring machines provide wide range of measurement and quality control for all types of parts (white, black, glossy, rubber ...). Micro-Vu automatic measuring machines are possible to extend by other sensors (accessories): touch probe, laser probe and rotary axis. These sensors serve to increase the efficiency of the entire process of quality control of measured parts.

All Micro-Vu machines can be extended with these sensors at any time, without any prior preparation.

Everything is controlled from the same one software and the different sensors can be freely combined within the measuring program.

Touch probe

- Exchanger rack for 6 modules

- Automatic exchange between touch/optic

- Automatic calculation of the approach vector

Laser probe

- Fast scanning of base surfaces

- Scanning glossy and matt surfaces

- Color display of scanned points

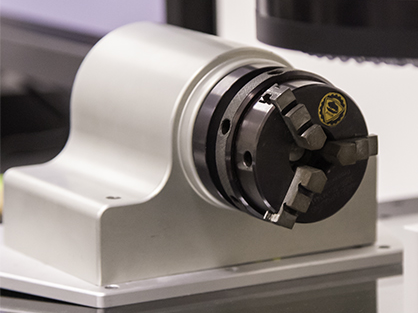

Rotary axis

- Positioning of the measured parts

- Vertical and horizontal clamping

- Including chuck

ADDITIONAL MACHINES

In addition to 3D multisensor machines, we also offer fast production 2D measuring machine, similar to a classic profile projector.

These machines are special for easy to use (just a click), compact design and quality production.

Due to the absence of 3D measurements, these machines are suitable for basic dimensional inspection, especially flat parts.

These machines are based on the automatic principle: PUT-PRESS-EVALUATE.

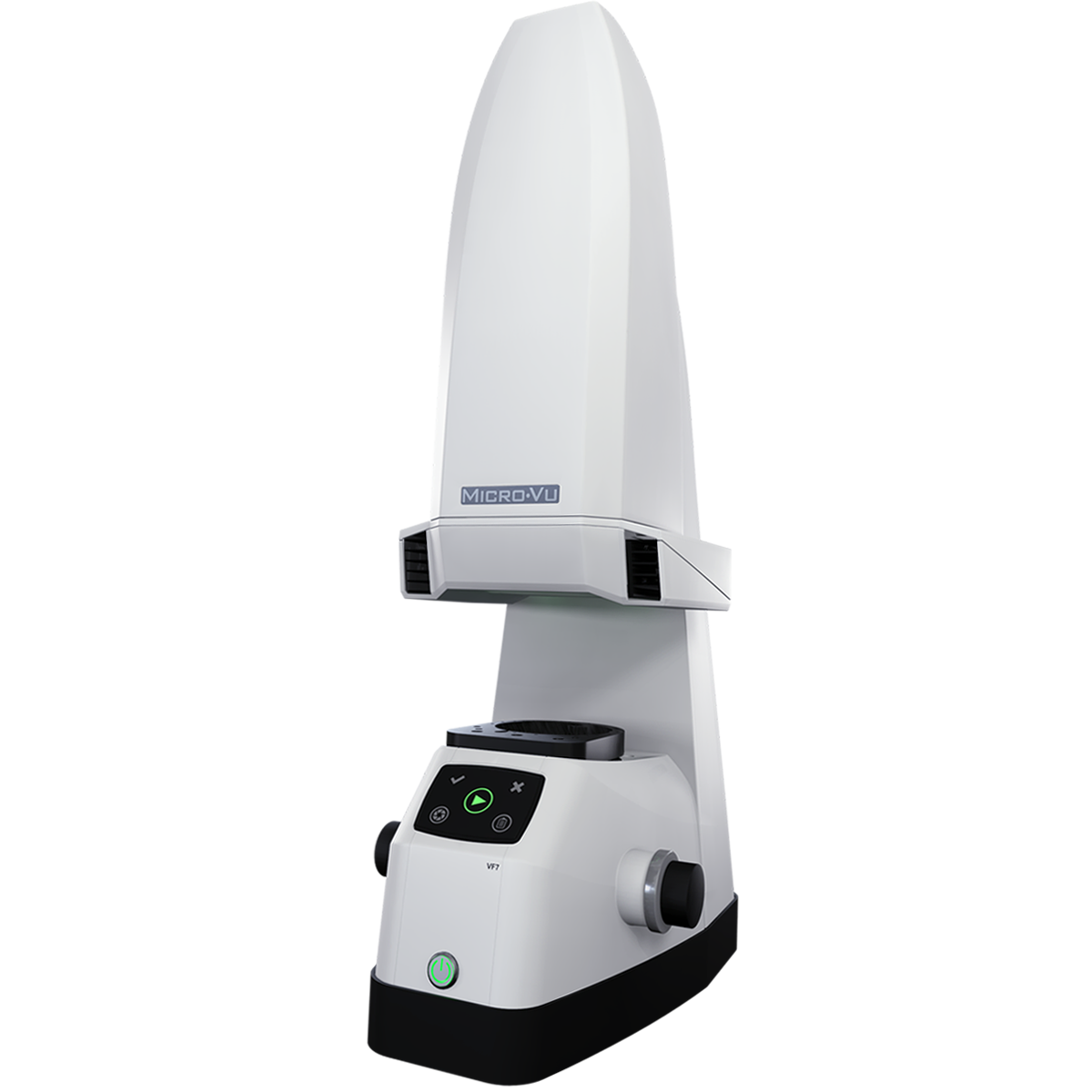

VF7

| Construction | table |

| Drive | automatic |

| Measuring range XY | 70 x 50 mm |

| Accuracy XY | 3 μm |

| Load capacity | 3 kg |

MACHINE SELECTION

The machine selection can be summarized in the following 4 steps:

- Defining requirements

- Consultation on a possible solution

- Demonstration of the machine free of charge (best directly on your parts)

- Recommendation of a suitable machine

Based on our many years of experience, we know that selection of the right measuring machine is a laborious process and you need to consider a number of factors. Don´t hesitate to discuss about it with Control Check employees.

The main factors are: type of production, frequency of measurements, size of the machine, operating conditions and much more. If you are interested in a consultation, don´t hesitate to contact us.

SERVICES

- Installation and calibration (accredited too)

- Repair and maintenance

- Training (basic, whosale, individual)

- Creating of measuring programs

- Telephone, online support

As well as the car, house or garden, you need to take care of the measuring technology on an ongoing basis, so that you can always rely on it. That's why we offer to our customers the highest quality service all the time. We perform technical calibration (accredited too) for all machines. We know all Micro-Vu machines in detail. Thanks to our own spare parts warehouse and remote diagnostics, we are ready for service intervention and we usually repair the machine during one visit.

We're happy to have if the machines are used for 100%, so we try to accent to pass on you maximum of our knowledge and experience during the training so that you don't bother with any part. If you don't happen to know what to do, we are here for you. Therefore, do not hesitate to contact us by phone or e-mail, we will be happy to help or explain everything to you. If you have too many of work to do, we will be happy to create measuring programs for you.

We provide complete services in the field of measuring technology for quality control. In our portfolio you will find machines of the largest producer of optical measuring technology in the world. Company Micro-Vu (USA) has been developing and manufacturing optical measuring instruments since 1959, has a rich history in the field of control and measurement technology for quality control. We are the only one official representative for the Czech Republic, Slovakia, and Poland.